Description:

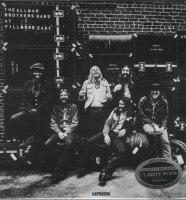

THE ALLMAN BROTHERS "Live At The Fillmore East" - Quiex SV-P 200 Gram Clarity Vinyl - LP SEALED, UNRELEASED & RARE

This Classic Records 200 G (2 LP set) of THE ALLMAN BROTHERS BAND AT FILLMORE EAST was transferred from the original analog 1/4" master tapes by Bernie Grundman at Bernie Grundman Mastering in Hollywood on Classic's "All Tube" stereo cutting system. Originally issued by Classic on Black vinyl with original artwork gatefold jacket and labels, this rare Clarity vinyl version was slated for release just prior to Classic Records sale to Acoustic Sounds in 2010, but sadly never released. A few copies survived and are made available for the first time ever. The Clarity Vinyl pressings are on Classic's 200 G Super Vinyl "FLAT" Profile and represent the ultimate in playback fidelity lacking both the tracking distortion from non-flat conventional profile records and the electrical distortion caused by the trace metallic particles in carbon black pressings. Recorded in 1970 at the illustrious Fillmore East and features an amazing 20-minute version of Whipping Post! There is so much clarity in this pressing that you can hear every detail including the tone of the guy's voice when he yells "Whippin' Post". This is a very rare item and not to be missed !

This very limited Clarity vinyl pressing was to be released before Classic Records was sold to to Acoustic Sounds in 2010, but was never released to the public - until now !

Background on Classic 200 G Super Vinyl Profile.

In 2003, Classic Records launched its now famous Signature Blue Note Mono reissue series. As part of that series Classic developed an "authentic" 200 gram LP profile that replicated that of an original Blue Note record from the 1950's. Comparing a test pressing on the new profile versus the same title on the normal 180 gram pressing it was discovered that the 200 gram version sounded significantly better. The 200 gram pressing sounded louder, with more definition and solidity of notes across all frequencies and there was more detail - particularly low level detail like room or hall sounds, pages being turned, musicians whispering and automobile sounds outside the studio all became easier to identify. At first it was speculated inside Classic Records that the extra weight resulted in the better performance as no one could come up with a better answer given that the stampers were the same as well as the vinyl pellets used on both 180g and 200g pressings. One day, Michael Hobson, the founder of Classic Records was discussing this unexplainable sonic discovery with the Legendary Mastering Engineer and Sheffield Records founder, Doug Sax when Doug, without hesitation stated "Ah Michael you've discovered the difference in a flat versus conventional profile". Puzzled, Hobson asked for an explanation which Sax described as going all the way back to 1950's mono pressings and what happened when stereo records came out in the early 1960's. Sax explained that in the 1950's when mono records had no vertical modulation (only lateral), pressing PolyVinylChloride PVC (plastic) records were more easily pressed on "Flat Profile" dies fitted to the pressing machines since the grooves on the mono stampers were all the same height (no vertical modulation). The molten vinyl was able to flow evenly across the stampers and fill properly during the molding (pressing) of the record. The problems started when stereo record cutting came into vogue producing stampers that had variable height grooves sticking up across the diameter of each stamper. Using the older mono pressing dies resulted in tremendous problems getting the areas between grooves of different heights to fill properly - a groove that is in front of another taller one often got passed over by the flowing molten vinyl resulting in "non-fill" which was audible and thus a "defective" record. Pressing plants don't like to press defective records and are always looking for high pressing yields or a s few rejects as possible.

To solve the problem, the engineers developed a new pressing die profile which tapers from the center of the die, flattens in the middle of the diameter and then tapers again toward the outside of the die. The new profile was "concave" rather than flat. When you put a flat stampers onto the concave dies the stampers distort and are no longer flat - the grooves are no longer perpendicular across the stamper and by association across a finished vinyl pressing. This new die profile created "back pressure" on the flowing vinyl and solved the "non-fill" problem with stereo pressings and resulted in higher yields which was great for pressing plants and good for record companies who wanted good prices on pressings. The problem was and still is that the new profile records don't sound as good as they could because they are not flat across their profile. Using a micrometer across the diameter of a 1950's mono records reveals that the thickness is virtually the same across the record's diameter from center label to outer edge but not so for a newer stereo profile pressing which is convex across its diameter resulting from the concave profile dies / distorted stampers. This is the dirty little secret that Classic had rediscovered was known to old school experts like Doug Sax who founded Sheffield Labs in the 1970's. After the discovery, Classic Records never looked back and all of its releases and re-pressings after 2003 were on the new 200 gram Flat Profile dies that were specially made for Classic. Some years later Classic discovered that the very same profile was used by JVC in Japan to produce the legendary UHQR pressings for Mobile Fidelity which are well known to sound better than the conventional Mobile Fidelity pressings of the same titles - it all makes sense now. The long and the short of this is that Classic 200g Super Vinyl Profile (Flat Profile) pressings are as good as it gets for proper playback without groove distortion from non-flat pressings - Period.

Background on Clarity Vinyl Pressings.

In 2008, Classic discovered that demagnetizing black vinyl records leads to better sound in playback. The engineers at Furutech in Japan, makers of a commercial record demag machine, explained that the carbon black that was added to PVC record pellets contained trace metal that became randomly magnetized and while spinning below an electro-mechanical transducer (phono cartridge) caused electrical distortion inside a cartridge during LP playback. Hence, demagnetizing a black vinyl record dramatically reduces the electrical distortion and leads to more "Clarity" in playback. Michael Hobson, founder of Classic Records reasoned that if the carbon black were removed then the result should be more Clarity in playback. Working closely with the PVC manufacturer Kenan, Classic developed its own proprietary "Clarity Vinyl" devoid of the problems with trace magnetic particles contained in black vinyl formulas. Clarity Vinyl represents the ultimate in vinyl formulations because it is comprised of over 90 % percentage of the highest quality co-polymer available - a key component in vinyl pellets used for manufacturing vinyl records. Further, Clarity Vinyl has no carbon black additive, common in vinyl formulas for LP’s. Carbon Black contains trace metals that become magnetized and cause “electrical distortions” in cartridges during playback that smears the sound. By taking out the Carbon Black, Classic Records is able to dramatically reduce the “electrical distortions” and thus bring more “Clarity” to the playback process, providing a more realistic musical experience to the listener and LP enthusiast.A Clarity vinyl pressing on a flat profile die is the absolute ultimate pressing possible and even a step above the JVC UHQR black vinyl pressings. Not to be missed - you can hear the difference ! [Masquer]